|

|

|

Whether youre starting from scratch, looking for a way to keep your plan up to date, processing meat, seafood or vegetables or operate a retail establishment, HACCP Pro is right for you.

You will quickly notice that each HACCP Pro step builds upon preceding steps, so you cant "jump tracks" or get ahead of yourself. This reduces the feeling that preparing a HACCP plan is an overwhelming process; instead, the whole process becomes a valuable experience which helps protect your company from possible contamination issues.

|

|

|

|

|

|

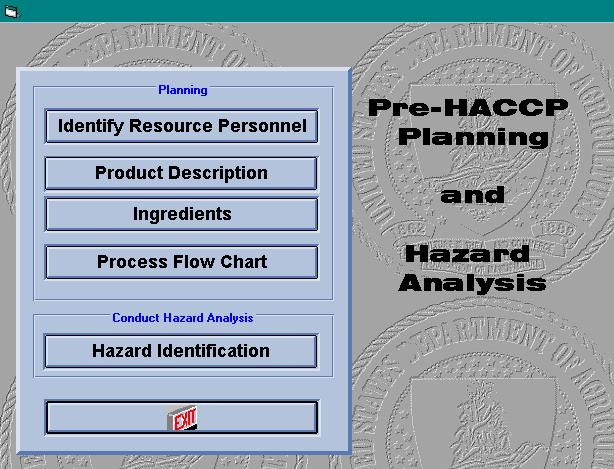

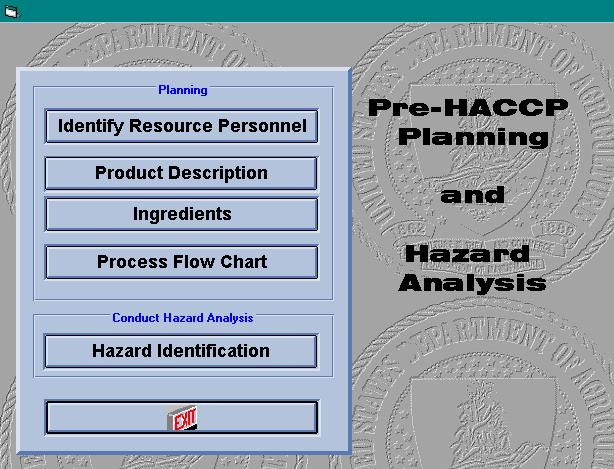

The screen lay out follows the seven principles of HACCP and utilizes large, easy to read fonts and controls. The user friendliness of the system keeps the preparer from getting lost in multiple menus, lists or tabs.

|

|

|

|

Identify Resouce Personnel

|

|

| HACCP Pro starts with the pre-planning steps necessary to starting a HACCP plan, such as identifying key personnel to serve on your HACCP team. Team members are identified by name, title, equipment expertise, experience and training. The entire team can be printed or one member at a time.

Government agencies will be looking for the caliber of the team when evaluating your plan. With HACCP Pro, youll be ready for any scrutiny of your team.

|

|

|

|

Product Description and Ingredients

|

|

| HACCP Pro then steps toward listing your products and separating the ingredients.

Common names, packaging and labeling are three of the many pieces of information gathered.

|

|

|

|

|

|

Now HACCP Pro gets down to the real job of creating your plan. The way each ingredient moves through your plant is depicted on a flow chart that allows diverging steps to merge into subsequent or preceding steps. The flow chart within HACCP Pro is very easy to follow. Some HACCP programs seemingly exaggerate the complexity of the flow chart, apparently to justify their own worth; in fact the user would be well advised to actually know the process flow before creating the flow chart within these programs. HACCP Pro keeps it simple. Taking one ingredient at a time, the flow chart can be created by simply walking the ingredient through your plant. If you forget a step or add a process later, you can insert or delete as many steps as you like. The deleted process is then removed throughout the entire plan. This saves time and frustration.

|

|

|

| Establish Critical Limits

|

|

|

Process steps are then examined to determine if they contain identifiable hazards.

|

| Hazards are then applied to the decision tree to establish if they qualify as Critical Control Points.

|

| With CCPs identified, the regulation expects plants to set up critical limits, monitoring procedures and verification checks for these points to assure that limits are maintained. The new regulation puts more of the responsibility of justifying procedures on the plant, justifying the validity of limits and practices.

|

| HACCP even requires you to list the name and location of reports and documents affiliated with the verification procedures.

|

| HACCP Pro assists the user in crossing the "T"s and dotting the "i"s.

|

| As you can see, developing a HACCP plan is much more than the finished document. In fact, the finished report should not become a document that sits on the shelf and gathers dust. HACCP Pro integrates with Recipe Pro to make your HACCP plan a "living" document.

|

| Each step can be printed to a hard copy and the process flow chart appears graphically with boxes and lines connecting the flow.

|

|

|

|

|

| Windows 95 or above

PC based computer with sufficient memory

Laser, Inkjet or DeskJet printer

|

|

|

|

|

| First license |

$ 350 |

| Additional licenses |

$10 ea |

| Annual Support Package |

$ 99 |

|

|

|